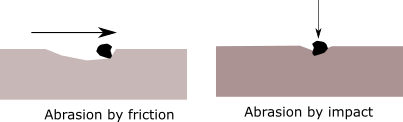

Abrasion of concrete is progressive loss of concrete mass due to mechanical degradation such as friction, grinding action, impact, overloading and local crushing. Vehicular movement and pedestrian traffic causes abrasion. The worst effect of abrasion is caused by vehicle with studded/chain tyres. Similarly, in industrial buildings, the concrete floors are subjected to impact load and scratching effects.

Factors affecting abrasion

The abrasion resistance of concrete depends upon the paste hardness, aggregate hardness and the bonding between paste and aggregate.

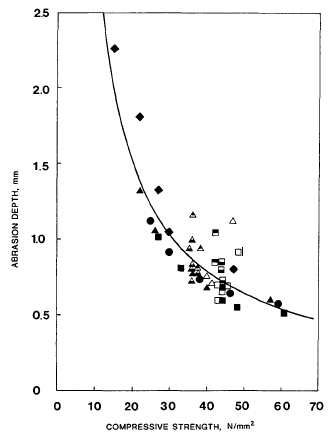

In general, higher the compression strength of concrete, higher will be its abrasion resistance (see figure below). But strength alone can not be taken as the parameter to estimate the abrasive behaviour.

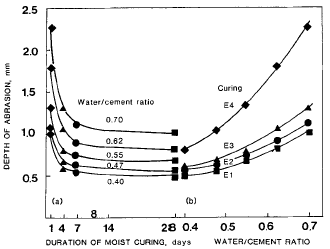

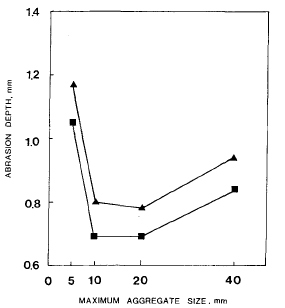

In an extensive study made by Dhir, the size of aggregate and curing time were observed to be dominant variables besides the compression strength (or w/c ratio). It was observed that the size of aggregate plays an important role for rate of abrasion (mainly in the case of impact loading). Due to higher stiffness of smaller aggregates, they are less prone to damage in impact loading, however, it is unclear why very small particles could be damaged easily.

The porosity of top layer is another main factor controlling the abrasion of concrete (Sadegzahed, 1987). A dense, well cured surface has higher hardness. It is also common practice to coat the abrasion prone surface with resistant material. For example, in bridge a flexible material (bitumen) is used while in industries a harder surface is made with addition of finer particles (e.g. silica). Other method to achieve abrasion resistant surface are as follows :

a) Surface finishing

b) Extensive curing

c) Aggregate proportioning

d) Cement proportioning

e) Addition of fly ash upto 30% has been found to increase abrasion resistance

f) Addition of fibres (steel, polypropylie)

Abrasion tests

Abrasion test in concrete can be done by adopting the procedure of following codes:

- EN 13892= BS 8204 Part 2

- ASTM C418, C779 and C944

- BS-8204 Part 2 (BIS 1999c)