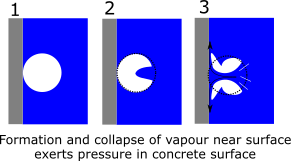

Cavitation is a physical process that leads to surface pitting caused by the collapse of vapour bubbles, which results in a sudden rise in local pressure. In this article, we explore how this phenomenon can damage concrete.

Damages by cavitation

Cavitation can damage the concrete in the following ways:

-

- Shock Waves Generated by Bubble Implosion: When vapour bubbles collapse or implode, they generate intense shock waves. These shock waves create high-pressure pulses that impact the concrete surface with significant force. Repeated exposure to these pulses can cause micro-cracks, surface pitting, and eventually lead to the degradation of the concrete’s structural integrity.

- Micro-Jets Due to Bubble Implosion: During cavitation, the collapse of vapour bubbles can produce high-velocity micro-jets of liquid. These micro-jets are directed towards the surface of the concrete at very high speeds. The concentrated impact of these jets can erode the concrete surface, remove material, and contribute to the development of pits and roughened areas, further weakening the structure.

- Collapse of Bubble Clusters: In cavitation, vapour bubbles often form in clusters. When these clusters collapse simultaneously, they generate a cumulative effect that is more damaging than the collapse of individual bubbles. The combined energy release from the collapse of multiple bubbles amplifies the impact on the concrete, leading to more severe erosion, larger pits, and accelerated wear of the material.

Where can cavitation occur?

Cavitation generally occurs in hydraulic channel and pipe where flow velocity is high -typically over 10 m/s at normal temperature and pressure. The high speed liquid creates a zone of sub-atmospheric pressure, resulting in the formation of vapour pockets. These vapour bubbles eventually collapses (implosion) and gives impact load on the concrete surface.

-

Pit formation due to cavitation

The pressure can be as high as several hundred MPa due to such implosion of bubbles. The continual effect may eventually loosen the concrete surface. The flow disturbance will worsen the effect of cavitation and accelerate the rate of damage. While a large portion of the concrete is damaged, the cavitation effect gradually decreases.

Cavitation modelling

The diameter of micro-jet due to bubble implosion can be approximated as

$$ d_i\cong0.1 R_o $$

where

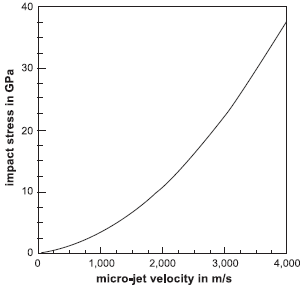

\(R_o \) is the radius of bubble before collapse. The velocity of jet can be as high as 4000 m/s and induces stress due to impact as shown in figure below.

For pit formation and its growth two criteria should be met viz. (a) the stress level should be high enough and (b) the duration of shock wave produced due to the collapse of bubble should be long enough to penetrate the existing cracks. For a rectangular pulse this criterion are represented by:

(a)$$\sigma_p^2.t_p=\frac{\pi.\gamma_M.E_M}{c_L} $$

(b)$$t_p=\frac{\pi}{2}.\frac{L_c}{c_L}$$

where

\(\gamma_M \) is specific surface energy,

\(E_M \) is Young’s modulus of elasticity ,

\(c_L \) is the velocity of longitudinal wave in the target material and

\(L_c \) is the length of preexisting crack.

The rate of erosion is shown in figure below as presented in the study by Morbar.

Prevention

Cavitation can be prevented by considering flowing in the design:

-Redesign to reduce flow velocity

-Aeration of water